3D Printing Services

As part of BSA Mouldings customer support services we have a product development unit at our Kings Lynn factory.

With a range of prototyping and product development equipment we can provide a comprehensive service to assist our clients move from initial concept to final production.

Three 3D printers, finishing equipment and a rapid moulding cell form part of our on-going investment in this area.

3D Printing and Prototype Manufacture

Our product development unit based in our Kings Lynn factory has a range of 3D printing equipment – capable of producing high resolution models in a wide range of materials.

A variety of 3D printers, finishing equipment and a prototype moulding cell form part of our on-going investment in this area

Rapid Prototyping

Is 3d printing for me?

3D printing can perform a useful role in visualizing how a design will perform in reality, both in terms of size/appearance and for some of its mechanical properties.

However, a prototype CNC-machined sample manufactured from a block of plastic can often be more useful – typically a machined sample is stronger and has properties more similar to the finished product – helping to select the exact type of prototype needed (machined, 3D printed, vacuum formed, vacuum cast or rapid tooling) is part of our development service.

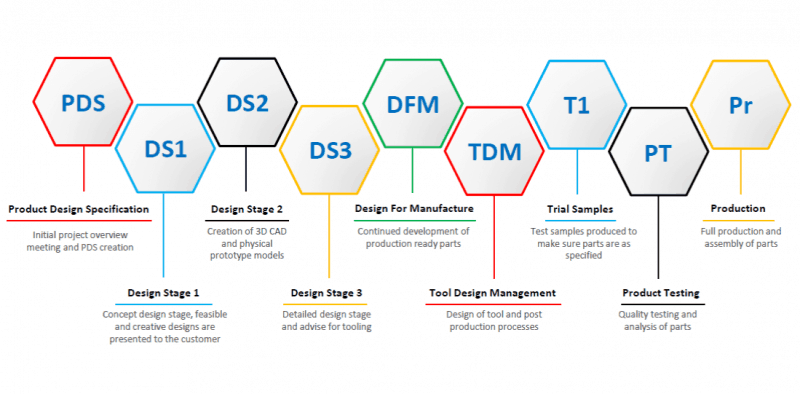

Product Development at BSA

Product Design

A prototype sample can only be produced from 3D design data. Although our customers often bring their own CAD information, BSA offer a complete 3D design service – using our established product development processes we ensure best practice engineering techniques are incorporated into our design service.

We also offer access to our comprehensive part and material library – with real world examples of functional design and material properties as well as an extensive database of reference samples and guides.

Free quote with design analysis

We are the UK’s plastic leaders in high-volume, close-tolerance injection moulding of both large and small custom plastic parts and products. We guarantee a high production output rate, low labour costs and a consistently precise tolerance.

- Simplify your operation

- Reduce your costs

- Distributed as single items, small consignments, or bulk shipments

3D Product Design

BSA offer a complete 3D design service – using our established product development processes we ensure best practice engineering techniques are incorporated into our design service

BSA Mouldings - A Partner You Can Trust

We pride ourselves on our straight-forward, honest approach and genuine care for your product. Quality-focused and committed to collaboration, our goal is to help you create a product that meets your exact specifications and expectations. Visit us to see the high standard of our factory for yourself!