BSA Mouldings are excited to have invested in a new central system and new gravimetric dosing units from Koch-Technik.

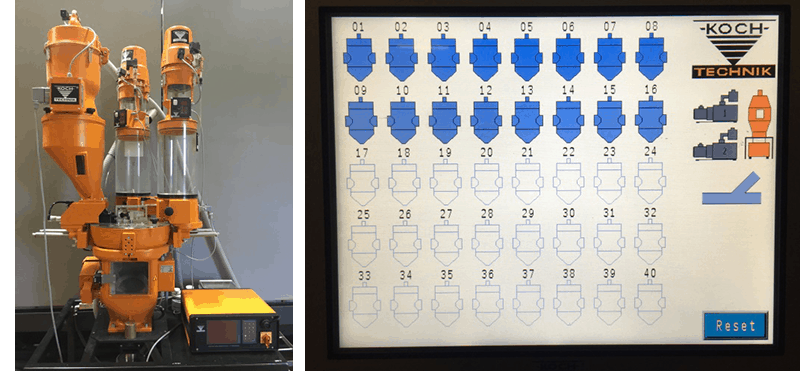

The central system has been installed to reduce the down time caused by having separate single phase hopper loaders on each machine. The single phase hopper loaders have two down sides; one is the fact that each unit has its own single phase motor and the second is that they each have their own problematic control system. The central system has a touch screen that is controlling all of the new simplified loaders from one central point and two large three phase vacuum motors to eliminate all the single phase motors and reduce downtime.

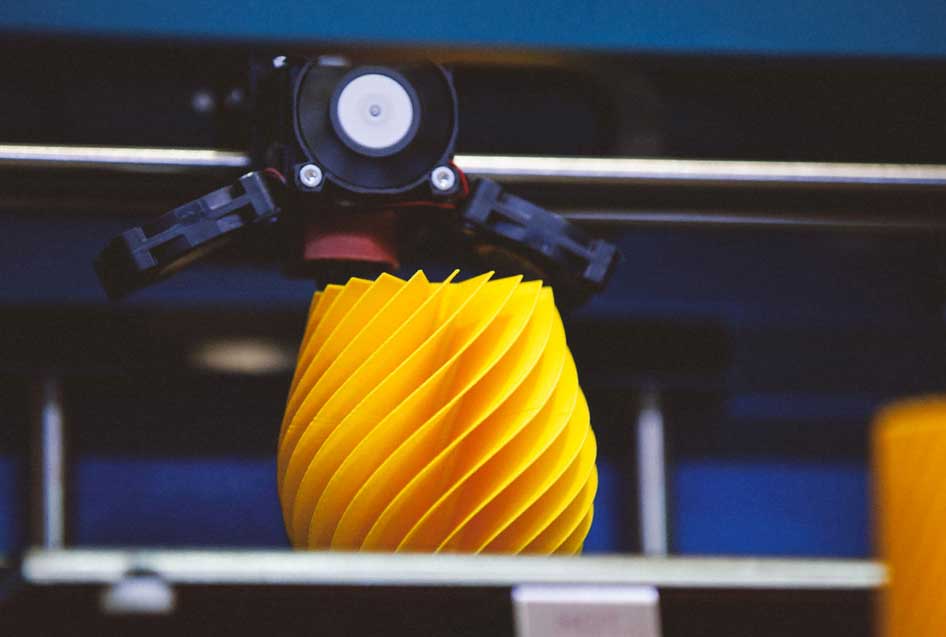

The Gravimetric dosing units add masterbatch and/or additives to the main material component with extremely high accuracy. These units weigh each component separately and collate a full report of all raw materials used. This is going to help maintain our stock accuracy and ensure that our finished products are of the highest quality.

Based in Germany, Koch-Technik are leading manufacturers of auxiliary equipment for polymer processing. They have a worldwide reputation of excellence in the plastic moulding industry. As well as producing a superior quality of finished product, the addition of the dosing units to our factory facilitates flexibility and efficiency – improving our ability to meet our customer’s needs.

Looking for Plastic Manufactures to help create your product ? Get in touch today !